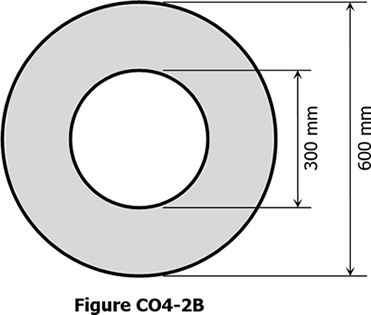

Situation

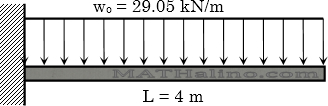

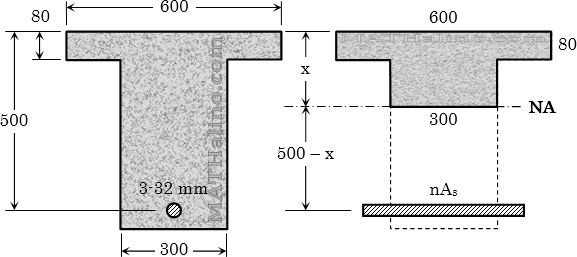

A concrete beam with cross section in Figure CO4-2B is simply supported over a span of 4 m. The cracking moment of the beam is 75 kN·m.

1. Find the maximum uniform load that the beam can carry without causing the concrete to crack, in kN/m.

| A. 35.2 | C. 33.3 |

| B. 37.5 | D. 41.8 |

2. Find the modulus of rapture of the concrete used in the beam.

| A. 4.12 MPa | C. 3.77 MPa |

| B. 3.25 MPa | D. 3.54 MPa |

3. If the hallow portion is replaced with a square section of side 300 mm, what is the cracking moment of the new section in kN·m?

| A. 71.51 | C. 78.69 |

| B. 76.58 | D. 81.11 |

- Read more about Hollow Circular Beam with Known Cracking Moment

- Log in or register to post comments