I need help on this question about direct stress, strain and dimensional change in a component

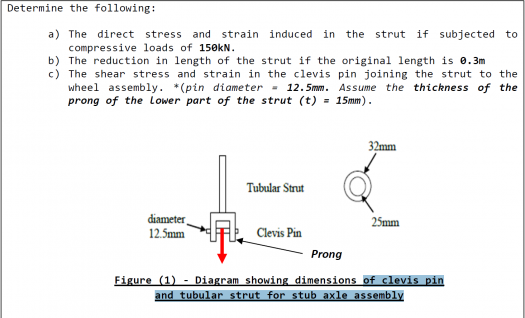

The under carriage strut of an aircraft in development is to be manufactured from

tube and has an internal diameter (25mm) and external diameter (32mm). It is

connected to the wheel stub axle assembly using a clevis pin arrangement (See

figure 1). The strut and clevis pin are all manufactured from the same grade of

steel which has a Modulus of Elasticity (E) of 210GPa and a Shear Modulus (G) of 80Gpa

I've been told to imagine the pin is hollow. Really been struggling with this one if anyone can help please.

thanks.

I've been told to imagine the

Please check how reliable is your source. Using a hollow pin for such a large load will only make the pin so thick, and it serves no other purpose other than making the pin thick, which ironically will serve no purpose to the assembly. And based on the problem description, it is not stated that the pin is hollow. The strut, however, is a hollow tube whose cross-section is shown in the figure, and it being hollow is also describe in the problem.

Part (a)

For direct compressive stress, use σ = P/A where P = 150 kN and A = 0.25π(322 - 252).

Part (b)

The need to reduce the length is to prevent the compression member from buckling. You can read about column effects of a compression member. Unfortunately, this topic is not yet in our site. You may Google "Euler's Formula for Buckling of Column".

Part (c)

There is a similar here only that the force applied to the clevis is tension:. See this: http://www.mathalino.com/node/54