Working Stress Analysis for Concrete Beams

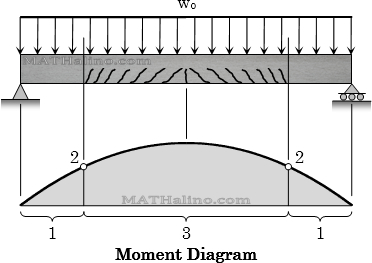

Consider a relatively long simply supported beam shown below. Assume the load wo to be increasing progressively until the beam fails. The beam will go into the following three stages:

- Uncrack Concrete Stage – at this stage, the gross section of the concrete will resist the bending which means that the beam will behave like a solid beam made entirely of concrete.

- Crack Concrete Stage – Elastic Stress range

- Ultimate Stress Stage – Beam Failure

Back to top

Concrete Beam Crack Stages

At section 1: Uncrack stage

- Actual moment, M < Cracking moment, Mcr

- No cracking occur

- The gross section resists bending

- The tensile stress of concrete is below rupture

At Section 2: Boundary between crack and uncrack stages

- Actual moment, M = Cracking moment, Mcr

- Crack begins to form

- The gross section resists bending

- The tensile stress of concrete reached the rupture point

At Section 3: Crack concrete stage

- Actual moment, M > Cracking moment, Mcr

- Elastic stress stage

- Cracks developed at the tension fiber of the beam and spreads quickly to the neutral axis

- The tensile stress of concrete is higher than the rupture strength

- Ultimate stress stage can occur at failure

Back to top

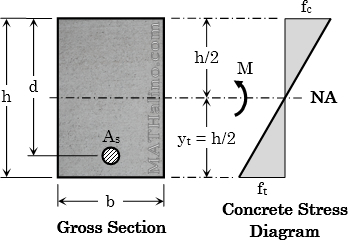

Working Stress Analysis – Uncracked Stage

The beam will behave elastically and remains uncracked. The tensile stress of concrete is below rupture.

Cracking Moment

NSCP 2010, Section 409.6.2.3

Modulus of rupture of concrete, $f_r = 0.7\sqrt{f'_c} ~ \text{MPa}$

Cracking moment, $M_{cr} = \dfrac{f_r \, I_g}{y_t}$

Where

$I_g$ = Moment of inertia of the gross section neglecting reinforcement

$y_t$ = distance from centroid of gross section to extreme tension fiber

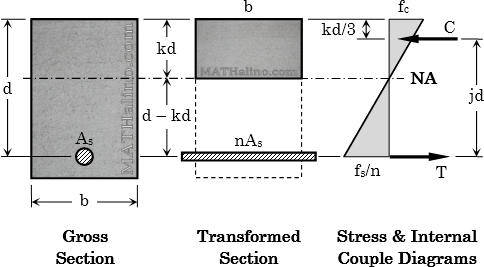

Working Stress Analysis – Cracked Stage

General Requirement

Actual Stresses ≤ Allowable Stresses

Internal Couple Method

Static equilibrium of internal forces

Factor k:

Factor j:

Moment resistance coefficient:

Moment capacity: Use the smallest of the two

$M_s = T \, jd = A_s f_s \, jd$

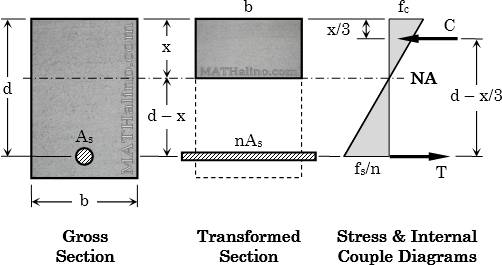

Transformed Section Method

Convert steel area to equivalent concrete area by multiplying As with modular ratio, n.

Location of the neutral axis from extreme compression fiber

Doubly reinforced: $\frac{1}{2}bx^2 + (2n - 1)A_s' (x - d') = nA_s(d - x)$

Cracked section moment of inertia (INA = Icr)

Doubly reinforced: $I_{NA} = \dfrac{bx^3}{3} + (2n - 1)A_s'(x - d')^2 + nA_s(d - x)^2$

Actual stresses (calculate using Flexure Formula)

$f_c = \dfrac{Mx}{I_{NA}}$

Tension steel

$\dfrac{f_s}{n} = \dfrac{M(d - x)}{I_{NA}}$

Compression steel for doubly reinforced

$\dfrac{f_s'}{2n} = \dfrac{M(x - d')}{I_{NA}}$