Solution to Problem 203 Stress-strain Diagram

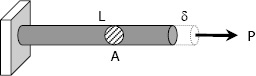

Problem 203

The following data were recorded during the tensile test of a 14-mm-diameter mild steel rod. The gage length was 50 mm.

| Load (N) | Elongation (mm) | Load (N) | Elongation (mm) |

| 0 | 0 | 46 200 | 1.25 |

| 6 310 | 0.010 | 52 400 | 2.50 |

| 12 600 | 0.020 | 58 500 | 4.50 |

| 18 800 | 0.030 | 68 000 | 7.50 |

| 25 100 | 0.040 | 59 000 | 12.5 |

| 31 300 | 0.050 | 67 800 | 15.5 |

| 37 900 | 0.060 | 65 000 | 20.0 |

| 40 100 | 0.163 | 65 500 | Fracture |

| 41 600 | 0.433 |

Plot the stress-strain diagram and determine the following mechanical properties: (a) proportional limits; (b) modulus of elasticity; (c) yield point; (d) ultimate strength; and (e) rupture strength.

- Read more about Solution to Problem 203 Stress-strain Diagram

- Log in or register to post comments